THE CLIENT

Selene is an Italian company that produces flexible packaging for industrial use and focuses on various stages of the production chain, such as the recovery of pressed bags from customers and collection centers, the recycling, washing, and regeneration of high-quality raw materials,

and the production of combined products using virgin and recycled polymers. Selene’s production approach is geared towards sustainability and environmental and social responsibility.

NEEDS

The company had several requirements to refine and optimize its production flow. It needed to achieve:

- lighter packaging

- reduced thicknesses

- excellent performance

- high quality

- environmental sustainability, with the use of recycled plastic (PE).

Specifically, the need was to carry out much more thorough checks on incoming material which, although of high quality, has much more uncertain characteristics than new material, and to take action if necessary.

THE PROJECT

Here too, ADR-Flow, our open-source support system for the automatic detection of industrial production defects based on Deep Neural Networks (DNN) and machine learning algorithms, demonstrated its flexibility and adaptability.

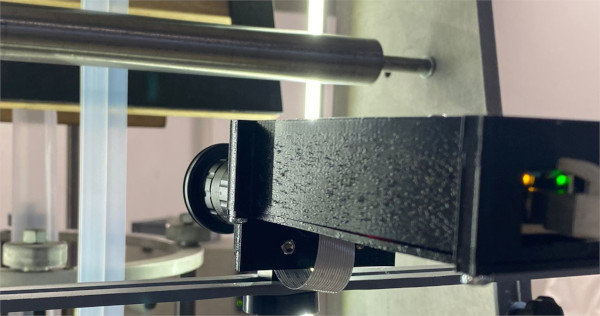

In this case, we decided to apply it to the pilot extruder, which was already being used to evaluate incoming material, but manually, keeping an operator busy for hours. The pilot extruder is fed with a sample of the batch to be inspected, after which the quality of the extruded product must be assessed. The ADR-Flow edge module, i.e., the part of the system that is in direct contact with the pilot extruder in this case, was configured with:

– a control station, which manages the interaction with the operator via a graphical user interface that allows the identification of the batch under examination; this also organizes the sending of photos and metadata to the remote server (cloud module)

– an “intelligent” camera, a real calculator (Raspberry, as in the other cases) with powerful built-in functions that allow for the automatic recognition of the presence of defects in the extrusion in real time.

The cloud module, on the other hand, consists of a virtual machine that has the task of:

- receive, record and analyze images

- allow specialized technicians to search for images, view them, and manually classify them—that is, determine whether they represent a defect or not—in order to use them for training and continuous performance testing of neural networks.

- support data scientists in training neural networks

- provide the system manager with a dashboard to monitor the system using simple graphs and tables showing the breakdown of defects over time, the image acquisition sequence on a daily, weekly, or monthly basis, an analysis of the quality of the recognitions performed, and, at the end of the acquisition, an assessment of the quality of the batch examined.

Once trained, the neural networks are sent to their respective cameras to perform real-time recognition.

RESULTS

The workflow has been improved and optimized: now the operator only needs to start the process and follow it randomly, while he or she can perform other tasks. Furthermore, this has allowed the creation of an archive of classified photographs that allow for the most precise tracking possible of the various batches of incoming material used.